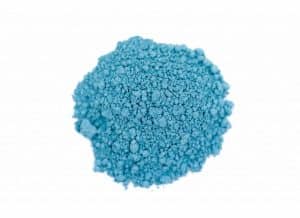

Description

- Medieval European painting harbours many secrets, which is why we often speak of the “secrets of the old masters”.

Painting was organized in guilds, and members of the guild traded recipes of certain processes only among other

members. No written account remains of many of these recipes which today pose a riddle to restorers and painters

alike.

One of the unsolved mysteries of painting technology is why azurite used in oil sometimes does not turn to green.

Azurite contains copper, which is notorious for changing its color in acidic environments, such as linseed oil. Now a

customer of ours – Michael Price – has developed a process to preserve the subtle blue hue of azurite in oil by coating

the particles with protein. As a by-product of this process, the pigment particles are sorted according to purity and size –

yielding many new and vibrant shades that can be used in oil painting. Scientific analysis supports the use of a protein

coat in historical copper paint pigments – the IRPA in Brussels found protein coatings on most of the pigments used by

the brothers Van Eyck.

We now offer from our own production this line of “MP” azurite pigments. Their hue is of special purity and varies

from color to color, according to particle size.

Our raw azurite is from eastern Congo in Africa. In the past we have had azurite from Marocco, Tsumeb, Arizona and

Mexico.

This is a very crude ore. We first separate by hand, then we separate by shaking table method, and finally by levitation.

The MP-process is orientated on old recipes of European and Chinese treatments of mineral pigments. This process

inactivates the reactivity of the minerals – to a certain extent – and “cleans” the surface.

On every crystal there are points of lower perfection. These points have a higher reactivity. The MP-process covers and

reduces the reactivity at these areas. Little particles are attached to bigger particles, making the separation of different

size particles difficult. The MP-process facilitates this separation.